Product Details

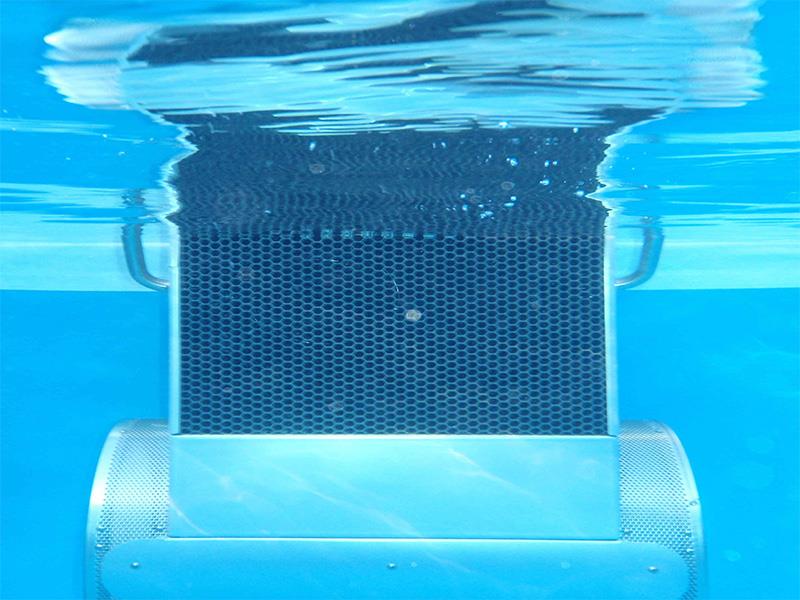

In the last few years the practice of the disinfection of both public and private swimming pools’ waters is consolidated, through the production of Hypochlorite directly in the pumping circuit, through electrolysis of the swimming pool’s water, previously additivated with Sodium Chloride in the measure of around 4g/lt.

The cell uses a variable number of small sized electrodes, around 100 cm2 each, and is controlled by a sensor which regulates its functioning based on the Hyperchlorite’s concentration level in the swimming pool.

The electrodes work alternatively as a cathode or an anode to the purpose of eliminating the incrustations of Carbonate of Calcium and Magnesium which form on the surface. For this reason all the electrodes are activated with the coating itself, generally Rhutenium Oxide + Iridium Oxide based and with a surface treatment of Titanium which makes them resistant to the very numerous inversions of polarity that the process requires.

We supplies both electrodes cut to measure according to the customer’s drawing and sheets of 1 m2 or more in the cases when the clients prefer to manage the cutting by themselves.

1. Standard Exporting package.

2. Original package or neutral package.

3. According to clients ' needs.

4. Shipped in10-35 days after payment.

Our Service

Spot delivery, including delivering small batches of goods

Provide wide-range and complete materials series products

Cutting plates, including complex shapes of materials and special processing and disposal

Cutting bars and strips

Our application technology expert provide the best material and recommendation

One-stop service